Products

Contact Us

Phone : +86 0531-85908792

Email:sales@rlaserpowersupply.com

Whatsapp: +86-15864507582

Wechat: +86-13295411923

Mobile :+86-13295411923

ZS-L150W-T CO2 laser power supply

This 150W CO2 laser power supply is specifically developed for removing residual and condensed dyes and oil stains on the inner surface of barrels in the textile industry The wavelength characteristics of CO2 laser determine that it can only process non-metallic materials and has no effect on metallic materials. Therefore, this laser cleaning machine uses CO2 laser tubes and laser power supplies as the main components. It has 10-16 CO2 laser tubes and laser power supplies working simultaneously on this cleaning equipment

ZS-L150W-T CO2 laser power supply

1.Summary:

This 150W CO2 laser power supply is specifically developed for removing residual and condensed dyes and oil stains on the inner surface of barrels in the textile industry . The CO2 laser's wavelength characteristics make it can only process non-metallic materials and has no effect on metallic materials. So, the laser cleaning machine can uses CO2 laser tubes and laser power supply as its main components. It generally has 10-16 PCS CO2 laser tubes and laser power supplies works at the same time on this cleaning equipment. In this situation, unstable input voltage may cause laser power supply's flyback or other component burnout then damage to the CO2 laser tube, which can cause the laser cleaning machine to shut down. The operator has to replace the laser power supply and laser tube, which increased the maintenance cost of the laser cleaning machine. To avoid this problem, our company has taken three measures: 1. It adds a 90-270V voltage regulator. When the input voltage is unstable, it can still ensure laser power supply works normally and doesn't burn out the flyback and other components. 2. It uses silicon carbide instead of traditional transistors that are prone to heat generation. Silicon carbide has low heat dissipation and durability features, which can ensure laser power supply's long-time stable works in high temperature and hot environment. It reduces the high failure rate of traditional CO2 laser power supplies. 3. It adopts automated surface mount assembly technology and HD camera detection technology. The automated SMT process ensures that electronic components are securely mounted on the PCB board, which guarantees sufficient output power and high resistance to harsh environments for the power supply. HD cameras are used to detect whether the components installed on the PCB board are firm, whether the welds are accurate, and whether the overall PCB board has defects, which ensures a high yied rate of laser power supplies and avoids unqualified laser power supplies caused by human errors. 4. 4/8 chennals LCD display screen is specially developed for this power supply. it can show 4 or 8 PCS laser power supply's output current,working status or failture code. Output current of 1,4 or 8 PCS laser power supplies can be roughly/fine adjusted at the same time. It is easy for operator to adjust laser cleaning machine's output energy to remove different thick dirty substance.

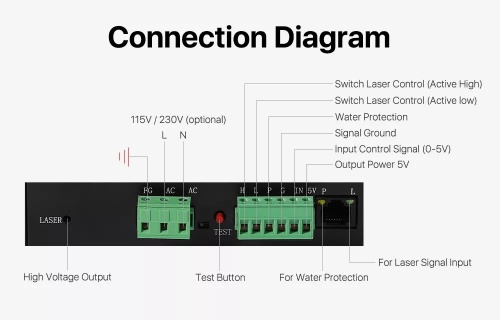

1.The 0 to 5V analog signals or PWM signals can be selected for controlling output power.

2.This 150W laser power supply laser power supply has good grounding protection: It can provide very safe protection for operators

3.With open circuit protection, the 150W laser power supply can work in an open-circuit state for a short time, which can avoid the damage on laser power supply caused by the bursting of the laser tube.

4.This 150W laser power supply has high efficiency and quick response with its zero current half bridge soft switching circuit. Thus it is easy to cooperate with most brand large power folded co2 laser tube.

5.The 150W laser power supply adopts high quality fans for cooling. It use Taiwan's bearing which make the fas run for very long time.

6.This 150W laser power supply selects H/L/P/G/IN/5V green terminal board to accept laser control signal and it has aluminum upper cover and base, galvanized sheet shell..

7.This high voltage laser power supply terminal control is simple and adapted to high and low level signals. TTL level can be used to control the start and stop of laser power. At the same time, an abnormal protection switch was added to detect if the external water is ventilated or not.

4.Technical specification:

lnput | Input voltage | AC90-270V±10% | ||

AC frequency | 47~440HZ | |||

Maximum input power | 1000W | |||

Maximum input current | 4.5A | |||

Output | Maximum output voltage | 45KV | ||

Maximum output current | 40mA (depending on the laser tubes of different manufacturers) | |||

Efficiency | More than 90% (Full load) | |||

Response speed | Not more than 1ms | |||

Control lnterace | TTL multilevel switching control,effective level can be high and low selection (see control wining diagram) | |||

Insulation | lnput-output | AC 1500V 1 minutes not more than 10mA | ||

lnput-shell | AC 1500V 1 minutes not more than10mA | |||

Output-shell | Connection | |||

Open Circuit Protection | Can be short circuit (requires a good grounding shell,while avoiding the positive electrode and the shell between the arc) | |||

Environmental Requested | Working temperature | -10℃~50℃ | ||

Storage of temperature | -20℃~75℃ | |||

Relative Humidity | Maximum 85%RH (non-condensing) | |||

Altitude | 100,000 feet of work 200,000 feet of storage,dose not work | |||

Cooling methods | Forced air cooling (fan cooling) | |||

Dimensions (LxWxH) | 302mmx142mmx90mm | |||

- Previous:ZS-L150W-Y CO2 Laser power supply

- Next:No Content

Telephone contact

TELEPHONE

+86-539-8058588

MOBILE PHONE

086-13295411923

2407603284

2407603284  ZRsunslaser

ZRsunslaser